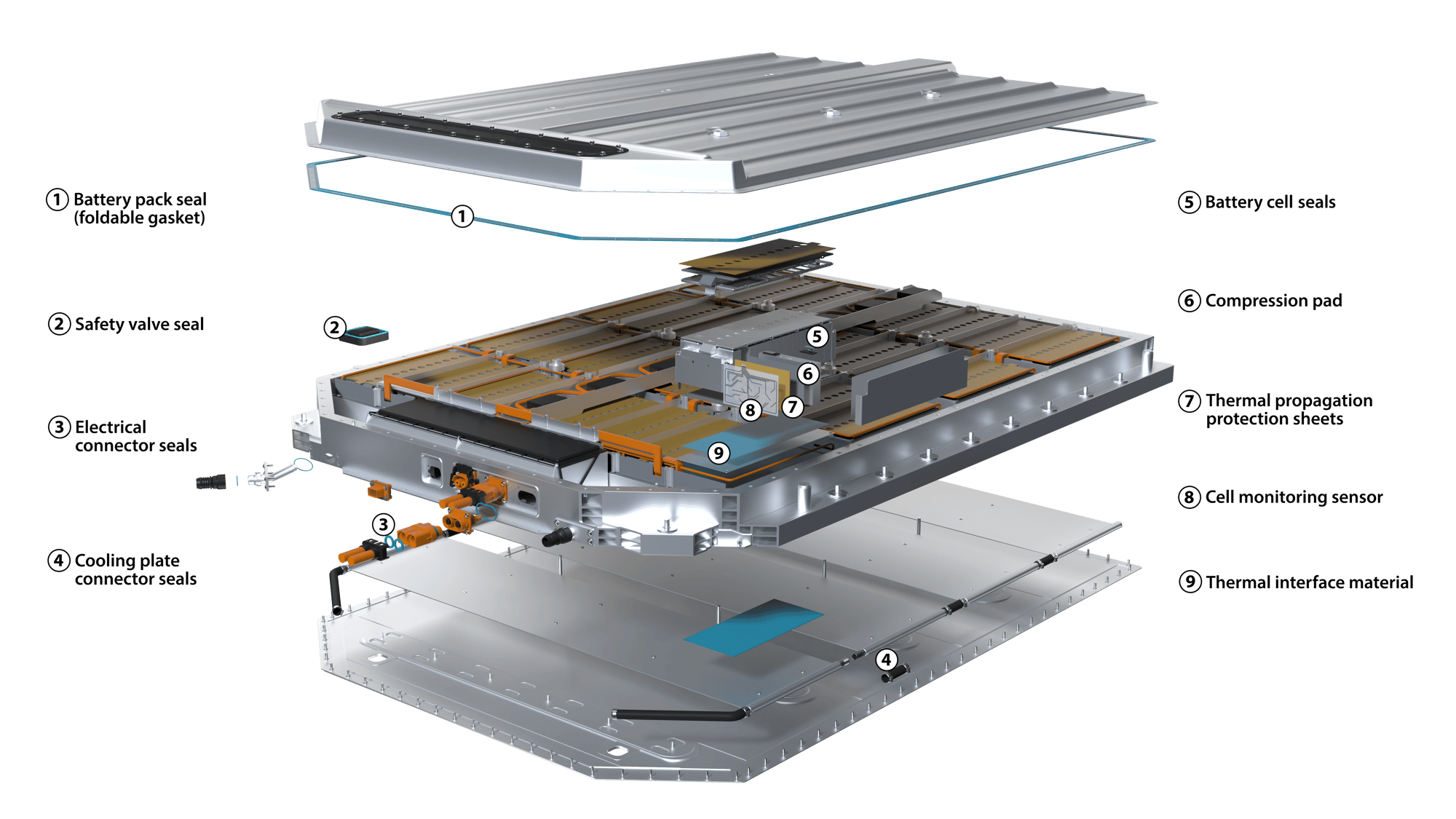

Battery sealing and thermal management solutions

Datwyler's solutions for battery systems

Datwyler produces a wide range of elastomer-based seals and thermal conductive components that increase safety and boost performance in the mobility sector. From critical seals for battery packs and cells to components for battery thermal management with special functionality, we design, develop, and produce high quality products customized to our customers’ specific requirements.

Thermal Interface Materials (TIMs)

TIMs play a crucial part in the thermal management of battery systems. By conducting the heat away from its source to the cooling systems TIMs guarantee to maintain optimal temperatures to ensure safe operation. This is essential for further development of battery electric vehicles (BEVs) and compliance with worldwide regulations.

Datwyler is able to optimize the compounds for TIMs in-house, taking into consideration the surrounding environment, the density of these materials and their hardness. With density, weight is also taken into consideration, as lightweighting is vital to extending the range of BEVs. Datwyler's 3D design capabilities ensure that the development process is accelerated.

Thermal barrier material

Datwyler is currently developing thermal barrier materials. Contact us for more information on development status or customized solutions.

Immersion cooling

While TIMs are used to boost the efficiency of indirect liquid cooling in battery systems, Datwyler has also developed sealing solutions supporting emerging immersion (direct) liquid cooling technology. A wide range of immersion cooling liquids from various chemical families and suppliers have been investigated and the chemical resistance and long-term stability of Datwyler's compound portfolio in relation to these fluids has been evaluated. We are confident in our ability to provide highly effective sealing solutions for most standard types of immersion cooling liquids.

Gasket technology

At Datwyler we have been focusing on stand-alone gasket solutions based on various polymer matrices. The composition of a rubber compound for a stand-alone gasket can also be adjusted according to specific environments, providing a lightweight and flexible solution that allows for the integration of additional material properties.

Additionally, Datwyler has developed a foldable gasket, which combines advanced elastomer materials with metal plates at intervals that can be specified and mounted according to unique part geometries. This combination enables a battery to be opened without damage to the pack housing should repair or maintenance be required, and also brings a wide variety of additional benefits.

Battery cell seals

For system-critical battery cell seals, we offer FKM and EPDM-based materials. These materials have been tested for contact with electrolyte for lithium ion batteries and show good chemical resistance as well as good thermal stability. In the harsh battery cell environment, these materials can be further customized to meet the requirements of customer specific solutions.